The bulk commodity sector in 2025 is bracing for a challenging year according to leading analysts. Market pressures such as reduced steel output, tariff barriers, and softer coal demand in India due to increased domestic production are all challenges the Bulk Commodity industry will have to overcome in 2025.

In the face of these myriad of challenges, is there another opportunity for the Bulk Commodity sector to drive innovation and efficiency in their operations that is perhaps being overlook? I’m referring to Integrated Supply Chains which are often overlooked when the supply chain is not controlled by one company alone but instead controlled by multiple parties who are only interested in their small piece of the Supply Chain puzzle.

So what is an Integrated Supply Chain?

An integrated supply chain is a strategic approach that seamlessly aligns and coordinates various components and processes involved in the creation and distribution of products or services. It represents a shift from traditional silo-based supply chain models to a collaborative and synchronized system that facilitates end-to-end visibility, communication, and decision-making across all stakeholders.

In this article I’m going to explore some of the challenges that traditional Bulk Commodity companies face with their supply chains, investigate some of the key benefits that a truly Integrated Supply Chain can deliver on and then look at how modern software applications such as SCIAR Systems can be leveraged to drive efficiencies in the supply chain such as real-time alerting, carbon emission reporting, compliance reporting, improved planning, enhanced scheduling and seamless integration to the underlying data in the operational systems that underpin the supply chain process from site to ship.

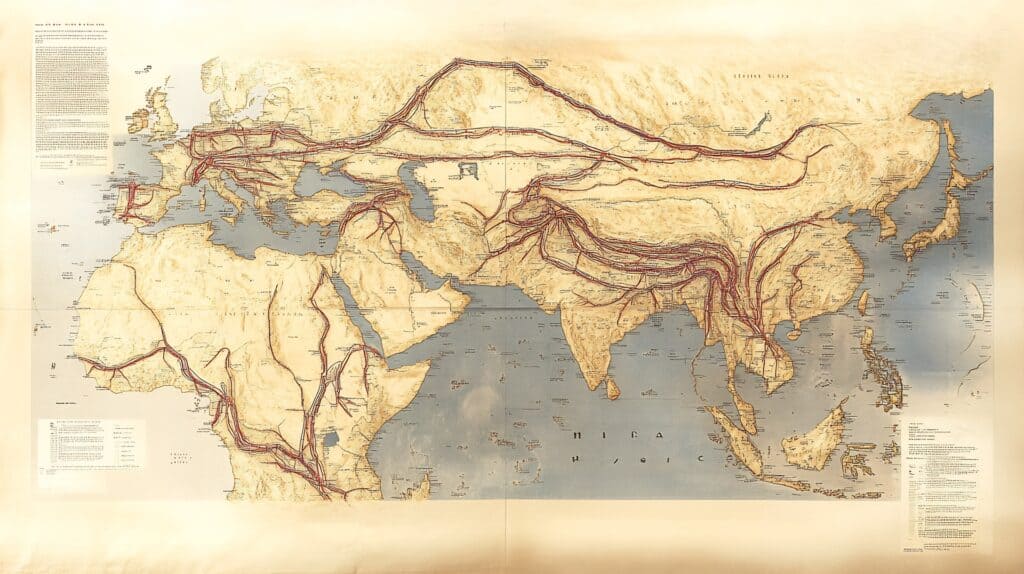

The concept of supply chains has existed for thousands of years, evolving from primitive trade routes to complex global networks powered by technology. Supply chains facilitate the movement of goods, services, and information, playing a crucial role in the growth of civilizations and economies.

The origins of supply chains can be traced back to early human civilizations. As societies transitioned from nomadic lifestyles to settled agriculture, they began exchanging surplus goods with neighboring communities. This trade created the first rudimentary supply chains, driven by the need for resources that were unavailable locally.

The fall of the Roman Empire disrupted trade routes, but supply chains adapted and continued evolving.

The Industrial Revolution (1750 – 1900) marked a major turning point in supply chain history. Mass production, mechanization, and improved transportation revolutionized the movement of goods.

The 20th century saw rapid advancements in supply chain management, driven by technological innovations, wars, and globalization.

Modern supply chains are complex, interconnected global networks that rely on digital innovations, automation, and sustainability initiatives.

An integrated supply chain is a cohesive, interconnected network where all components of the supply chain—from suppliers and manufacturers to distributors and retailers—work together seamlessly to optimize the flow of goods, information, and finances.

Some key characteristics of an integrated supply chain include:

The integration typically spans several dimensions:

Benefits of an integrated supply chain include reduced costs, improved customer service, faster time-to-market, better inventory management, enhanced risk management, and increased agility to respond to market changes.

Modern integrated supply chains often leverage technologies like cloud computing, IoT, AI, and advanced analytics to enable this seamless coordination and visibility.

Unfortunately in the Bulk Commodity space a lot of the supply chains would be best categorised as non-integrated which are also commonly referred to as fragmented, siloed or stove-piped supply chains.

Non-integrated supply chains are characterized by:

In a fragmented supply chain, you typically see:

| Aspect | Integrated Supply Chain | Non-Integrated Supply Chain |

|---|---|---|

| Information Flow | Seamless data sharing across all functions and partners | Limited information sharing with data silos and barriers |

| Visibility | End-to-end visibility across the entire supply chain | Limited visibility, often restricted to individual departments |

| Decision Making | Collaborative decisions based on complete supply chain data | Isolated decisions based on limited local information |

| Technology Systems | Connected, interoperable systems with unified data | Disconnected legacy systems requiring manual data transfer |

| Planning Process | Synchronized planning across all supply chain functions | Independent planning with minimal cross-functional input |

| Inventory Management | Optimized inventory based on total supply chain needs | Excess buffer inventory at multiple points due to poor coordination |

| Response to Disruptions | Rapid, coordinated response with real-time alerts | Delayed awareness and fragmented response to issues |

| Partner Relationships | Strategic, collaborative partnerships | Transactional, often adversarial relationships |

| Performance Metrics | Aligned metrics focused on overall supply chain performance | Conflicting departmental KPIs that may undermine overall efficiency |

| Cost Structure | Lower total costs through elimination of redundancies | Higher costs from inefficiencies and duplication of efforts |

| Process Standardization | Consistent processes across the supply chain | Varied processes between departments and partners |

| Communication | Regular, structured communication channels | Ad-hoc communication with frequent misalignment |

| Risk Management | Holistic risk assessment and mitigation | Fragmented risk management with potential blind spots |

| Continuous Improvement | Systematic approach to end-to-end optimization | Siloed improvement initiatives with limited impact |

| Carbon Reporting | Unified emissions tracking and reporting | Fragmented data collection hampering accurate reporting |

Unfortunately, Bulk commodity supply chains frequently experience stove-piping and fragmentation issues, often more severely than other industries due to their unique characteristics:

These fragmentation issues in bulk commodity supply chains typically manifest as excess inventory buffers, suboptimal logistics planning, delayed response to disruptions, and difficulty implementing end-to-end visibility initiatives.

Luckily there is a solution to eliminate stove-piped applications in the Bulk Commodity Sector and that is deploy the world-leading Supply Chain Integrated Autonomous Rail (SCIAR) Application.

SCIAR is a cloud-based Software as a Service (SaaS) application designed to manage the logistics process from customer contact to site execution & loading through to final reconciliation & vessel dispatch.

SCIAR has automated the touch points involved in the Bulk Commodity Logistics chain & integrated them into a single platform. This allows users to not only manage the end-to-end logistics process but also to receive real-time alerts when there are anomalies in the systems that require immediate attention.

In addition, SCIAR has built-in reporting capabilities that provide a comprehensive audit trail of your logistics operation as well as comply with Australian Government mandatory Scope 3 carbon emissions reporting requirements.

SCIAR has a number of high-level business benefits that help to drive efficiencies in your Bulk Commodity Supply Chain:

The bulk commodity sector struggles with significant operational disconnects between various stages of the supply chain. Mining operations, processing facilities, logistics providers, and shipping terminals frequently operate as isolated units with limited information sharing.

This fragmentation manifests in several critical ways:

The Supply Chain Integrated Autonomous Rail (SCIAR) application addresses these challenges through a cloud-based SaaS platform specifically designed for the bulk commodity sector. By integrating the entire logistics process from initial customer contact through loading, reconciliation, and vessel dispatch, SCIAR eliminates the fragmentation that plagues traditional approaches.

SCIAR’s real-time alert system transforms reactive management into proactive intervention. When anomalies occur anywhere in the supply chain, stakeholders receive immediate notifications, allowing them to address issues before they escalate into costly problems.

The application’s integrated approach to data management ensures compliance with increasingly stringent regulatory requirements, including Australia’s Scope 3 carbon emissions reporting mandates. By automatically collecting and processing emissions data across the entire supply chain, SCIAR simplifies what would otherwise be a complex, manual reporting process.

Perhaps most importantly, SCIAR optimizes the critical connection between product availability and shipping schedules, ensuring that rail resources are utilized efficiently. This synchronization reduces costly bottlenecks and demurrage charges while improving overall throughput.

The built-in compliance tracking and reporting functionality further streamlines operations by automating what traditionally requires significant manual effort. This not only reduces administrative overhead but also improves accuracy and auditability.

By replacing siloed applications with an integrated platform, SCIAR provides the comprehensive visibility and coordination capabilities that bulk commodity supply chains desperately need. The result is a more resilient, efficient, and transparent operation capable of meeting both current challenges and future demands in this critical sector.

What are your biggest bulk commodity supply chain challenges? OR even if you have general questions about this post. Feel free to reach out to our team at SCIAR Systems and Schedule a Call.

Nick Ogle has have over 30 years of experience in Enterprise IT, spanning roles from engineering, sales to marketing across Australia, the USA, and APJ for various IT vendors. Nick has also founded his own consulting businesses.

Nick is passionate about entrepreneurship and software innovation that drives positive change. Currently, he is the Sales & Marketing Manager at SCIAR Systems, a Newcastle-based SAAS startup, where he is helping commercialize their groundbreaking Bulk Commodity Logistics and ESG software solutions.

Nick is well credentialed to talk about issues in Enterprise IT issues such as supply chain integration due to his extensive experience in cloud computing architectures, application design and general industry background in IT.

For more information on Nick and to find articles that have been written on the IT sector in the past, then feel free to look at his LinkedIn profile or browse some of the additional articles Nick has written for SCIAR Systems.